Polysilazanes (OPSZ, PHPS)

Properties and Applications

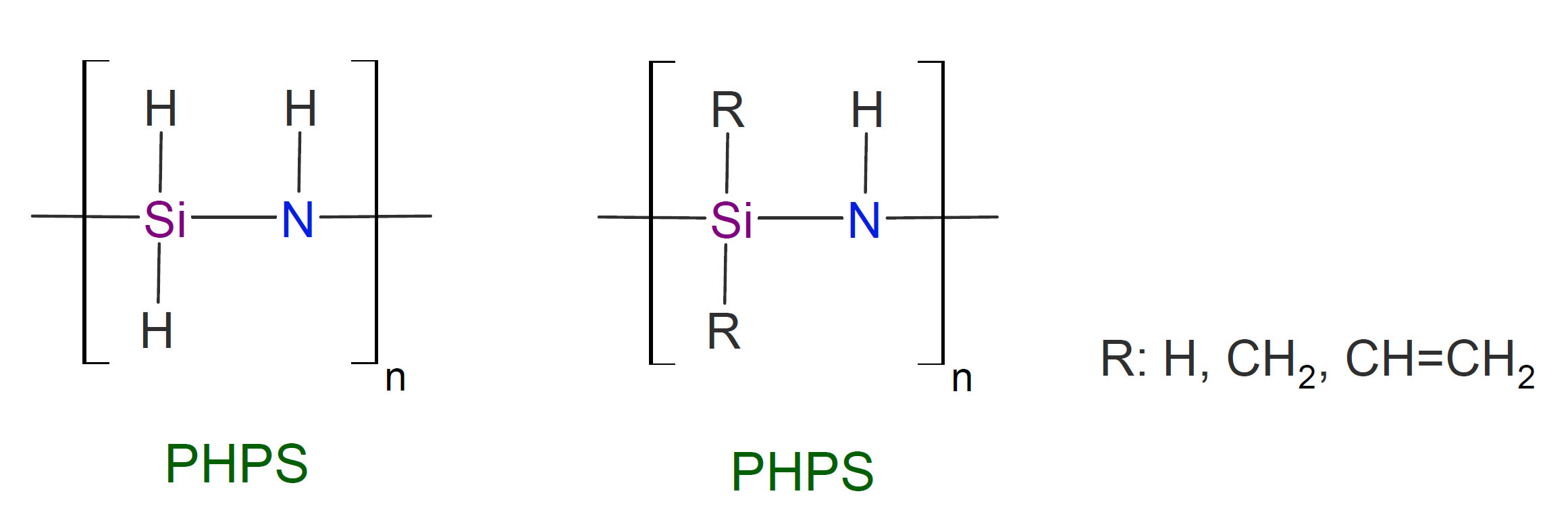

Polysilazanes are a class of very heat stable inorganic polymers with a polymer backbone made up entirely of silicon-nitrogen bonds with either only hydrogen substituents attached to each silicon and nitrogen atom (perhydro-polysilazanes PHPS, -NH-SiH2-) or with additional organic substituents attached to each silicone (organo polysilazanes, OPSZ, -NH-SiR2-). The pendent groups are typically hydrogen, alkyl, and/or aryl groups. Thus an almost unlimited number of different polymers belong to this class. However, only a small number if silazane monomer/polymers are commercially available.

Polysilazanes are known for their high temperature and oxidative stability1; excellent scratch, abrasion and impact resistance; high hardness (up to 5H for OPSZ and 9H for PHPS); and high resistance to weathering and many chemicals. Most or all of these properties are superior to those of polysiloxanes. Polysilazanes with nonpolar organic side groups have also outstanding non-stick and easy clean properties which are almost as as good as those of fluoropolymers (PTFE).2

Polysilazanes are mainly used as precursors to SiO2, Si3N4 and SiC ceramics. Pyrolysis / oxidation of these precursors provide a convenient method for preparing silicon-based ceramic products, such as fibers, coatings and fiber-reinforced ceramic-matrix composites (CMCs) which are often difficult to manufacture with conventional ceramic processing methods. However, the use of polysilazanes has been severely limited by the high price and by lack of availability. The most important applications appear to be protective and heat resistant coatings in the electronic, automotive, and aerospace industry (exhaust systems, engine parts, heat exchangers, ovens and electronic devices). Organo silazanes are also sometimes incorporated into one- and two-component coatings for car / train exteriors and architectural elements. These products protect smooth and non-absorbent surfaces against graffiti and dirt.

Manufacturers & Brands

Producers |

Brands |